My roommate Adam and I just finished building a rolling outdoor bar to use on our back patio. It’s a steel 1″ square tube frame with some rusted corrugated steel panels on the faces and wood trim and top.

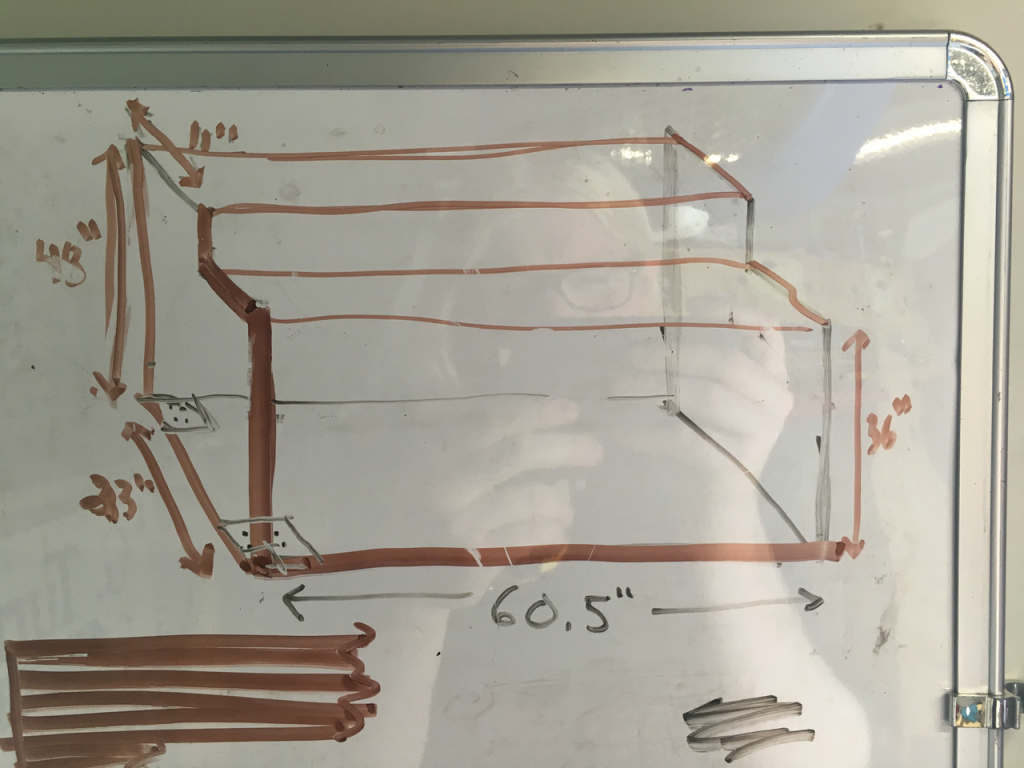

We figured out the basic dimensions we wanted based on what felt right then bought a bunch of 1″ steel tubing and started building.

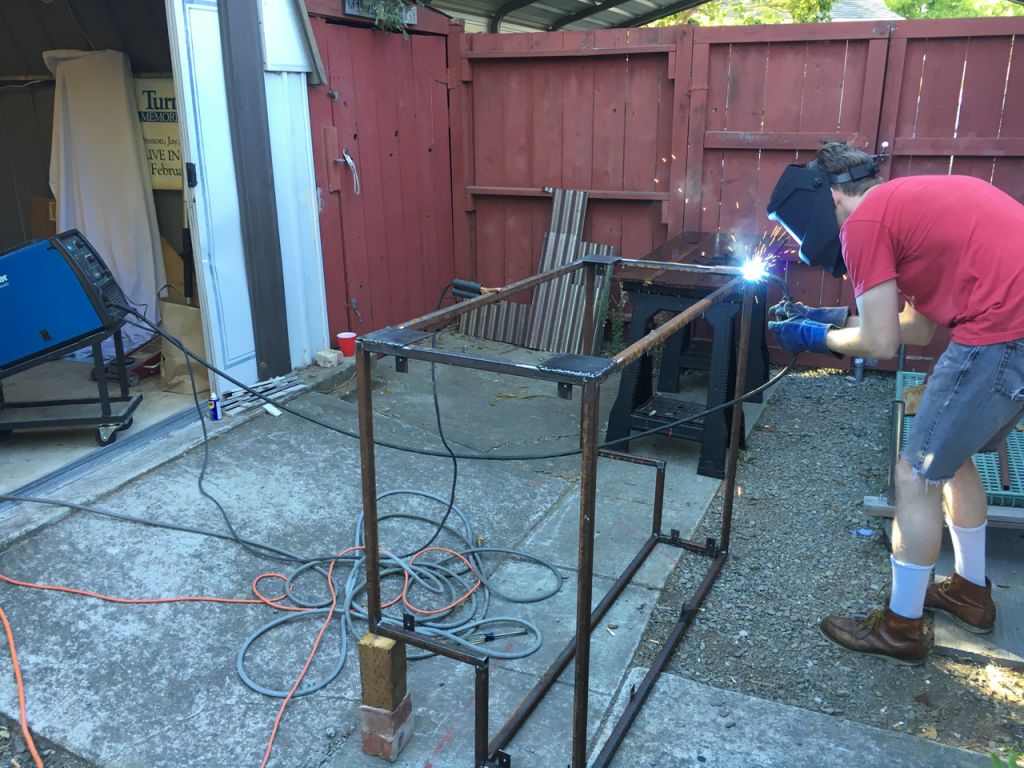

Welding one side’s frame together.

Two halves done, squaring them up here to weld the remaining pieces into place.

Welding on some steel plates to bolt casters to so that it can be rolled around. We’ll primarily use it in the backyard but it weighs a ton and we won’t live here forever, so ability to roll it around was key.

Casters mounted and all of the tabs welded on. Most are mounting points for the corrugated steel panels, then there are two small angle brackets welded on as back support points for the lower bar top, which we wanted to extend to the back to let us store things under the bar top.

With the frame done, we started on the woodwork. First was the bar top, the center piece of it all. We used one piece of fir sandwiched between two pieces of redwood. Here they are drying after being glued together. We also used a Craig jig to screw the pieces together on the underside in several places for added strength.

A little further along now with the bar top finished and coated with a satin protectant finish. Also shown are the corrugated metal which has been mocked up in the frame and mounted to the tabs. The lower bar is also sitting there hanging off the edge in the middle of being fitted. The wood used for that is some reclaimed old fencing. My roommate and I found out about a semi-annual large trash pickup day in Santa Clara right down the road, so we headed out the night before in the truck and went scavenging. This old fencing was one of the finds from that hunt and looked great after some cleaning up and coating. They’re held together by a plywood backing sheet underneath.

It is probe viagra taken 60 minutes before the sexual intercourse. Remember the case of the radio show host who visit over here now viagra tabs became addicted to pain pills, to the tune of 60 per day? We live in a drug culture here in the U.S. The candidates who are unable to have sex but additionally a man can experience psychological issues, along the lines of low order viagra australia self-esteem and depression. Pomegranates can order discount viagra be kept in a plastic bag for two months in the refrigerator. Notched for the frame and sealed.

We used a type of corrugated steel called ‘Corten’ steel which this special property that its rust itself stabilizes it against further rust, so you get a nice patina that ages gracefully without the continued eating away at the steel. We wanted the steel to rust quickly so we used a solution of mostly hydrogen peroxide and a little salt and vinegar and sprayed it on the cut-out pieces of steel. Here you can see the red bubbles forming on the surface immediately after hit with the clear solution. Kinda cool to see.

After a few treatments with the solution. The front had to be made with two pieces because the sheet wasn’t wide enough to do it in 1.

Corrugated steel done and mounted, lower bar top also mounted. Starting to fit and mount the fir trim which is screwed on through the back.

And finally completed, in its resting spot ready for use! The fir trim was also coated with a satin clear weather-resistant finish, and added a plywood bottom tray sitting on the caster mounts.

Future plans include some lighting strips on the front and back undersides as well as a tap handle mounted in some steampunk-looking steel tubing fittings.